When it comes to concrete formwork, the choice of materials can significantly impact the quality and efficiency of construction projects. Among the various options available, F14 grade plywood stands out as a preferred choice for builders. This article delves into the reasons behind this preference, exploring the characteristics, benefits, and applications of F14 Formply in the construction industry.

Table of Contents

ToggleUnderstanding F14 Grade Plywood

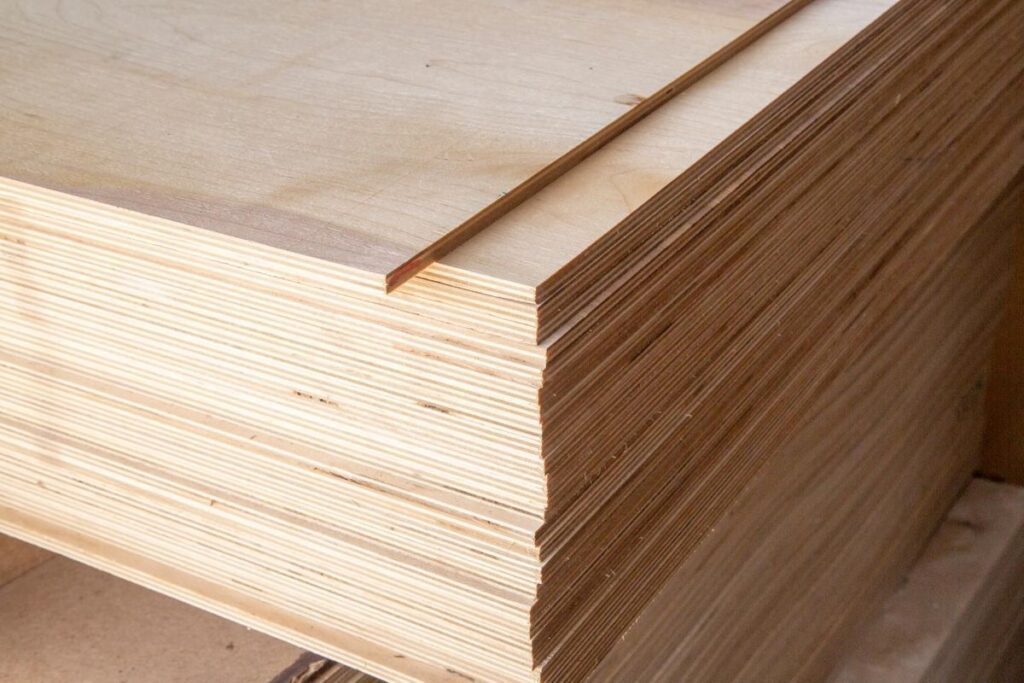

F14 grade plywood is a specific type of plywood designed primarily for use in concrete formwork. Its unique properties make it ideal for constructing formwork for concrete slabs, columns, and walls. This high-strength plywood is manufactured to withstand the rigours of construction, ensuring durability and reliability throughout the building process.

Available in standard sizes of 2400mm x 1200mm and 1800mm x 1200mm, F14 Formply comes in thicknesses ranging from 12mm to 25mm. This versatility allows builders to select the appropriate size and thickness for their specific project requirements, enhancing its usability across various applications.

Key Characteristics of F14 Formply

One of the standout features of F14 Formply is its high strength-to-weight ratio. This characteristic makes it a cost-effective option, as it can support heavy loads without adding unnecessary weight to the formwork structure. Builders appreciate this balance, as it simplifies handling and installation.

Additionally, F14 Formply exhibits excellent moisture resistance, which is crucial in concrete applications where exposure to wet conditions is inevitable. This moisture resistance not only prolongs the lifespan of the plywood but also ensures that the concrete sets correctly, leading to a high-quality finish.

The Advantages of Using F14 Formply

Builders favour F14 Formply for several compelling reasons. Its durability is a primary factor; the plywood can withstand the harsh conditions often encountered on construction sites. This durability translates to fewer replacements and repairs, ultimately saving time and costs.

Another significant advantage is the reusability of F14 Formply. Unlike some other materials that may degrade after a single use, F14 Formply can be reused multiple times, making it an environmentally friendly choice. This reusability aligns with the growing emphasis on sustainability within the construction industry.

Cost-Effectiveness

F14 Formply is often regarded as a cost-effective solution for concrete formwork. Its high strength-to-weight ratio means that builders can achieve the necessary structural integrity without overspending on materials. This cost efficiency is particularly beneficial for large-scale projects where budgets are tight.

Moreover, the reduced need for frequent replacements further enhances its cost-effectiveness. Builders can allocate their resources more efficiently, focusing on other critical aspects of the construction process.

Applications of F14 Formply in Construction

F14 Formply is versatile and suitable for a wide range of applications in the construction sector. It is commonly used in formwork for concrete slabs, columns, beams, and shutters. Its adaptability allows it to be employed in both residential and commercial projects, making it a go-to choice for builders across various sectors.

In addition to traditional formwork applications, F14 Formply can also be used in non-specified applications where a high-quality finish is not essential. This flexibility allows builders to utilise the material in various contexts, further enhancing its appeal.

Innovations in Formwork Solutions

The construction industry is continually evolving, and innovations in manufacturing are enhancing the quality and sustainability of formwork plywood. Recent developments, such as eco-friendly formwork solutions launched by companies like Aluma Systems, are aimed at reducing waste and improving sustainability in construction projects. These innovations complement the existing benefits of F14 Formply, making it an even more attractive option for builders.

As the demand for sustainable construction practices grows, F14 Formply’s reusability and durability position it as a frontrunner in eco-conscious building materials. Builders can feel confident that their choice not only meets structural requirements but also aligns with environmental goals.

Market Trends and Growth Potential

The global formwork plywood market is experiencing significant growth, with projections indicating an increase from US$ 6,377.3 million in 2024 to US$ 7,850.5 million by 2034, reflecting a CAGR of 2.1%. This growth is driven by the rising demand for efficient and sustainable construction materials, with F14 Formply at the forefront of this trend.

As builders seek to optimise their construction processes and reduce environmental impact, the popularity of F14 Formply is likely to continue rising. Its unique characteristics and advantages make it a staple in the toolkit of modern builders.

Conclusion

F14 grade plywood has established itself as a preferred choice for concrete formwork due to its durability, moisture resistance, and cost-effectiveness. Builders appreciate its high strength-to-weight ratio and reusability, which contribute to efficient construction practices. As the industry moves towards more sustainable solutions, F14 Formply’s role is set to expand, making it an essential material for future construction projects.

In summary, the combination of innovative manufacturing, versatility, and environmental benefits positions F14 Formply as a leading choice for builders looking to enhance their concrete formwork solutions. With its proven track record and ongoing developments in the industry, F14 Formply is poised to remain a cornerstone of construction materials for years to come.

Learn about: How to Choose the Right Formply Australia for Your Construction Project